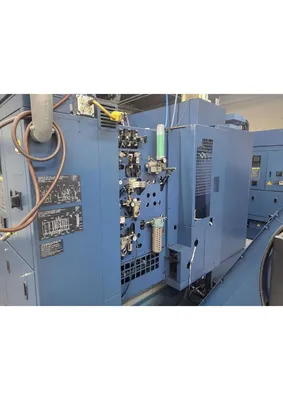

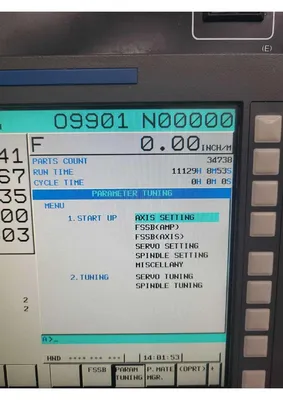

2013 MATSUURA MAM 72-63V, 5-axis, vertical machining center offers 29.921" X-axis travel, 12,000 rpm spindle, 240-tool capacity, with high-pressure coolant and probes. Equipped with G Tech 30i, CoolJet system, and chip conveyor. Pallet prepped.

MATSUURA G TECH 30i

RENISHAW OMP60 / OMP40

RENISHAW TS27R / NC4 / OTS

RENISHAW RMP600 / OMP400

BLUM LASER TOOL SETTER

BLUM WORKPIECE PROBING SYSTEM

FULL 5-AXIS SIMULTANEOUS MACHINING CAPABILITY

HIGH-CAPACITY TOOL MAGAZINE (240 TOOLS)

2-PALLET SYSTEM

AUTOMATIC PALLET CHANGER (APC) INTEGRATED

CHIP CONVEYOR

MIST COLLECTOR / COOLANT MIST EXTRACTOR

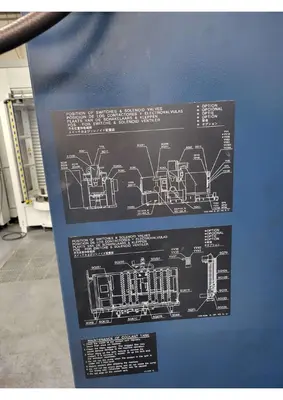

HIGH-PRESSURE COOLANT SYSTEM (HPC) – 300-1000 PSI

TSC - COOLJET HIGH-PRESSURE COOLANT TANK

AUTOMATIC TOOL LENGTH MEASUREMENT / BROKEN TOOL DETECTION

TOOL LIFE MANAGEMENT SYSTEM

THERMAL COMPENSATION SYSTEM

SIMULTANEOUS 5-AXIS SOFTWARE PACKAGE

REMOTE MONITORING / MATSUURA IOT CONNECT

COOLANT THROUGH SPINDLE (CTS / TSC)

SPINDLE CHILLER / OIL COOLING UNIT

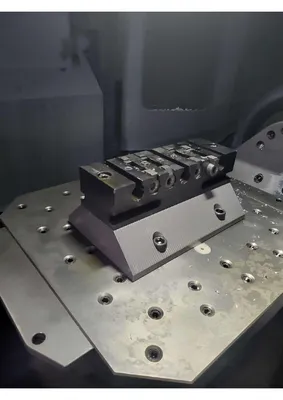

5-AXIS VISES (SCHUNK), ZERO-POINT CLAMPING (EROWA)

LASER TOOL MEASUREMENT

BACKUP TOOL CAPABILITY

COOLANT FILTRATION SYSTEM (BAG)

SURGE PROTECTOR / LINE CONDITIONER

UPS BATTERY BACKUP

INTEGRATED FIRE SUPPRESSION SYSTEM

OFFLINE TOOL PRESETTER (ZOLLER)

MACHIN IS PREPPED FOR PC18 (18 PALLET) CONFIGURATION

We use cookies to improve your experience. Privacy Policy.