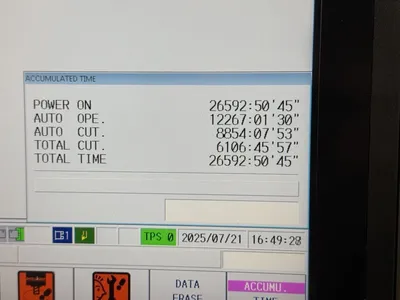

Seller does not have the work for this machine, this is their only Mazak. Tech that ran the machine is no longer there, so they are getting rid of the machine Great Machine, NO HOLDERS

Specifications (subject to buyer verification):

Maximum Swing 25.9"

Maximum Swing over Cross Slide33 25.9"

Maximum Cutting Diameter: Chucking 25.9"

Maximum Cutting Length 59.8"

MAIN SPINDLE SPECIFICATIONS (L):

Spindle Nose A2-8

Spindle Bore 3.58"

Maximum Bar Work 3.0"

Spindle Speed 35-4,000 RPM

Spindle Index (Programmable). 0.0001 Deg.

3,600,000 Positions

Spindle Horsepower (Cont./30 Mins) 30/40 HP (AC)

Spindle Torque (25% ED) 534 ft-lbs.

SECOND SPINDLE SPECIFICATIONS (R):

Spindle Nose A2-8

Spindle Bore 3.58"

Maximum Bar Work Optional-depends on current chuck package

Spindle Speed 35-4,000 RPM

Spindle Index (Programmable) (0.0001 Deg. C-Axis Optional)

Spindle Horsepower (Cont./30 Mins) 30/35 HP (AC)

Spindle Torque (30 min.) 369 ft-lbs.

TURRET AND TOOLING SPECIFICATIONS:

Type of Turret 1 position w/ATC

Magazine Capacity 72

Tool Selection Method Random Shortest Path

Tool to Tool ATC Time 1.3 sec.

Max. Tool Dia. w/All Pockets Full 3.54"

Max. Tool Dia. w/Adjacent Pockets Empty. 4.92"

Max. Tool Length (From Gage-Line) 15.75"

Maximum Tool Weight 26.5 lbs.

ATC Tool Shank. CAPTO

Rotary Tool Spindle Speed 15-12,000 RPM

Rotary Tool Spindle Horsepower (20% ED). 30 HP (AC)

Rotary Tool Torque (20% ED) 88.5 ft-lbs

AXIS TRAVELS:

B-Axis 240 Degrees

(-30 deg. to +210 deg. 0.0001 degree increments)

Y-Axis 9.84"

X-Axis 24.21"

Z-Axis 62.4"

Second Headstock W-Axis 61.96"

AXIS RAPID RATES:

X & Z-Axis 1969 IPM

Y-Axis 1575 IPM

Second Headstock W-Axis 1181 IPM

B-Axis 40 RPM

C-Axis 555 RPM

GENERAL SPECIFICATIONS:

Floor Space (WxL) 110.2" x 193.3"

Machine Height 107.1"

Total Power Required (Machine Only) 81.95 KVA

NOTE: Actual Machine Main Transformer

KVA Rating Will be Greater.

Air Requirements 71 PSI/12.7 CFM

Machine Weight (36t) 34,172 lbs.

Equipped With (subject to buyer verification):

Mazatrol Matrix 2 CNC Control

19” Color LCD

EIA/ISO Code Input Function

User Macro (Common Variables: 600 Pairs)

Additional EIA/ISO Functions

3-D Coordinate Conversion

GOO Slope Constant

Shape Compensation for Rotary Axes

Cylindrical & Polar Coordinate (EIA)

Milling-Spindle Synchronous Tapping

EIA 1st Spindle & Mill Spindle Simultaneous Rotation

Inch/Metric Conversion

CARDBUS I/F (2-Slot)

LAN Port

USB I/F

Y-Axis Control

Absolute Positioning System (Linear Axes)

XYZ Pitch Error Compensation Input

Coolant Through Milling Head

213 PSI Thru Coolant / Flood Simul-Flowable

Prep for Chip Covneyor (Side/Consep)

1st Spindle Bore 3.58”

1st Spindle Motor 40 HP

1st Spindle Speed 4000 RPM

C-Axis 0.0001 Degree Increment (1st Spindle)

2nd Spindle Motor 35HP

2nd Spindle Speed 4000 RPM

2nd Spindle C-Axis with C1-C2 0.0001 Degree Increments

Chuck Air Blast (2nd Spindle)

72 Capto-Tool Magazine

Rotary Tool Spindle Speed 12,000 RPM

B-Axis 0.0001 Deg/Contouring (Requires EIA/ISO)

Automatic Tool Eye

Auto Chuck Jaws Open/Close (1&2 Spindle)

Chuck Open/Close Confirmation (1&2 Spindle)

Coolers for Ball Screw (X-Axis)

Relocation Device

MT Connect Preparation

Windows 7 Operating System for Mazak Machine Control

Mazak Superflow S8-1000 High Pressure Coolant 1000 PSI/8GPM

Auto Power Off (Breaker Trip)

Automatic Parts Catcher w/Ejec (3.15” Dia x 5.9” L x 11 lbs)

Chip Conveyor Side Disposal (Hinge Type)

Auto Pecking Cycle with Load Detection

Prep for Multi & Flash Tool System

ATS ML3-580S Barfeed

Shuck Rota THW Plus Chuck Pkg w/Kitagawa Y-1225RE

(2) Kitagawa B-210X 10” Chucks

We use cookies to improve your experience. Privacy Policy.