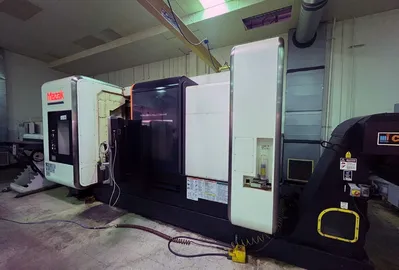

2012 Mazak Integrex i-300S Intelligent /Multi-Tasking Twin Spindle CNC Turning Center w/ Mazatrol Matrix 2 Controls, 36-ATC, “Y” Axis, “B” Axis Live Tooling, 4000 Main and Sub Spindle RPM, 12,000 Milling RPM

Specifications (subject to buyer verification):

Maximum Swing 25.9"

Maximum Swing over Cross Slide33 25.9"

Maximum Cutting Diameter: Chucking 25.9"

Maximum Cutting Length 59.8"

MAIN SPINDLE SPECIFICATIONS (L):

Spindle Nose A2-8

Spindle Bore 3.58"

Maximum Bar Work 3.0"

Spindle Speed 35-4,000 RPM

Spindle Index (Programmable). 0.0001 Deg.

3,600,000 Positions

Spindle Horsepower (Cont./30 Mins) 30/40 HP (AC)

Spindle Torque (25% ED) 534 ft-lbs.

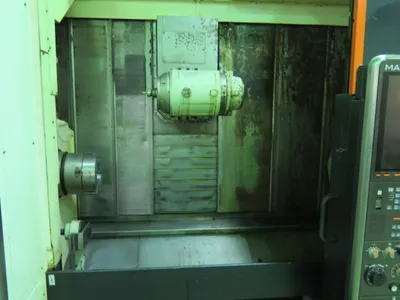

SECOND SPINDLE SPECIFICATIONS (R):

Spindle Nose A2-8

Spindle Bore 3.58"

Maximum Bar Work Optional-depends on current chuck package

Spindle Speed 35-4,000 RPM

Spindle Index (Programmable) (0.0001 Deg. C-Axis Optional)

Spindle Horsepower (Cont./30 Mins) 30/35 HP (AC)

Spindle Torque (30 min.) 369 ft-lbs.

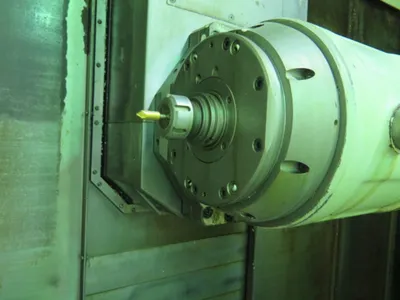

TURRET AND TOOLING SPECIFICATIONS:

Type of Turret 1 position w/ATC

Magazine Capacity 36

Tool Selection Method Random Shortest Path

Tool to Tool ATC Time 1.3 sec.

Max. Tool Dia. w/All Pockets Full 3.54"

Max. Tool Dia. w/Adjacent Pockets Empty. 4.92"

Max. Tool Length (From Gage-Line) 15.75"

Maximum Tool Weight 26.5 lbs.

ATC Tool Shank. CAPTO

Rotary Tool Spindle Speed 15-12,000 RPM

Rotary Tool Spindle Horsepower (20% ED). 30 HP (AC)

Rotary Tool Torque (20% ED) 88.5 ft-lbs

AXIS TRAVELS:

B-Axis 240 Degrees

(-30 deg. to +210 deg. 0.0001 degree increments)

Y-Axis 9.84"

X-Axis 24.21"

Z-Axis 62.4"

Second Headstock W-Axis 61.96"

AXIS RAPID RATES:

X & Z-Axis 1969 IPM

Y-Axis 1575 IPM

Second Headstock W-Axis 1181 IPM

B-Axis 40 RPM

C-Axis 555 RPM

GENERAL SPECIFICATIONS:

Floor Space (WxL) 110.2" x 193.3"

Machine Height 107.1"

Total Power Required (Machine Only) 81.95 KVA

NOTE: Actual Machine Main Transformer

KVA Rating Will be Greater.

Air Requirements 71 PSI/12.7 CFM

Machine Weight (36t) 34,172 lbs.

2012 MAZAK I-300 1500

KEN OKUYAMA DESIGN

MAZATROL MATRIX 2 CONTROL

19" COLOR LCD

EIA/ISO CODE INPUT FUNCTION (STANDARD)

ADDITIONAL EIA/ISO FUNCTIONS (REQUIRES EIA/ISO)

3-D COORDINATE CONVERSION

GOO SLOPE CONSTANT

SHAPE COMPENSATION FOR ROTARY AXES (G61.1)

CYLINDRICAL (G07) & POLAR COORDINATE (G12) (EIA)

MILLING-SPINDLE SYNCHRONOUS TAPPING

EIA 1ST SPINDLE & MILL SPINDLE SIMULTANEOUS ROTATION

INCH/METRIC CONVERSION

CARDBUS I/F (2-SLOT)

LAN PORT

USB I/F

M0575A12CJO

ROLLER GUIDES

Y-AXIS CONTROL

ABSOLUTE POSITIONING SYSTEM (LINEAR AXES)

SF205A12CJO

X, Y, Z PITCH ERROR COMPENSATION INPUT

COOLANT THROUGH MILLING HEAD

15KG/213 PSI THRU COOLANT/FLOOD SIMUL-FLOWABLE $9300.00

1ST SPINDLE BORE DIA.91MM (3.58")

1ST SPINDLE MOTOR AC 30KW (40HP)

1ST SPINDLE SPEED 4000 RPM

2 C-AXIS 0.0001 DEGREE INCREMENT (1ST SPINDLE)

2 SECOND SPINDLE MOTOR AC26KW (35HP)

2 SECOND SPINDLE SPEED 4000 RPM

2ND SPINDLE C-AXIS WITH C1-C2 0.0001 DEGREE INCREMENTS $3400.00

CHUCK AIR BLAST (SECOND SPINDLE)

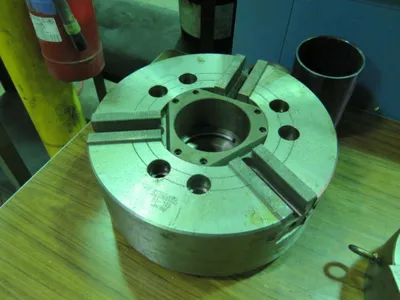

**15" THRU-HOLE CHUCK

B15A08 (MAIN SPINDLE ONLY)** $6700.00

10" THRU-HOLE CHUCK

B210A0815X (1ST SPINDLE)

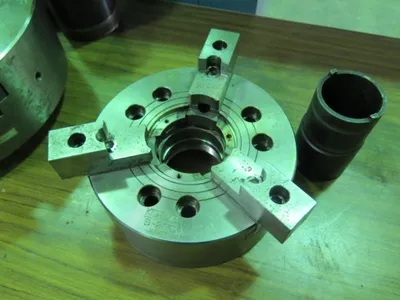

10" THRU-HOLE CHUCK

B210A0815 (2ND SPINDLE)

36 KM-TOOL MAGAZINE $4200.00

ROTARY-TOOL SPINDLE SPEED 12000 RPM

B-AXIS 0.0001 DEG/CONTOURING (REQUIRES EIA/ISO)

TOOL EYE (AUTOMATIC)

2 AUTO CHUCK JAWS OPEN/CLOSE (1&2 SPINDLE)

2 CHUCK OPEN/CLOSE CONFIRMATION (1ST & 2ND SPINDLE)

OPERATOR DOOR INTERLOCK WITH LOCK-SWITCH

HYDRAULIC PRESSURE INTERLOCK

COOLERS FOR BALL SCREW (X-AXIS)

POWER TRANSFORMER FOR NORTH AMERICAN MKT

RELOCATION DEVICE

MT CONNECT PREPARATION

WINDOWS 7 OPERATING SYSTEM FOR MAZAK MACHINE CONTROL.

HAND GREASE PUMP (LG-400) (TO REFILL CENTRAL LUBE RES.) $50.00

GREASE CARTRIDGE EP-1 (2 SETS) (FOR CENTRAL LUBE RESERVOIR) F) $20.00

TOOL RADIUS COMPENSATION /5-AXIS $1500.00

5-AXIS MACHINING PACKAGE $7400.00

MAXIMUM PROGRAM SIZE :8MB $1500.00

ETHERNET OPERATION FUNCTION $1400.00

$5000.00 TOOLING CERTIFICATE FOR KENNAMETAL KM TOOLING $2900.00

CHIP CONVEYOR SIDE DISPOSAL (CONSEP WS) USE FOR 60" $30700.00

AUTO PARTS CATCHER $2000.00

CERTIFIED FOUNDATION DRAWING (WILL CHECK IF AVAIL)

LNS QUICK LOAD SERVO 80-S2 SHORT MAGAZINE BARFEED $23200.00

BAR-FEEDER ONE STANDARD LINER (SIZETBD)

RETROFIT PARTS FOR AUTO PARTS CATCHER MAX PART SIZE IS DIA. 80MM X L=150MM X 5KG $13900.00

PREPARATION FOR CHIP CONVEYOR

(SIDE/CONSEP OR HINGE) US

We use cookies to improve your experience. Privacy Policy.